In the ever-evolving packaging industry, rigid trays and custom boxes have emerged as key players, driven by consumer demand for sustainability, branding, and product protection. These packaging solutions are not only crucial for product safety but also serve as powerful marketing tools. This article explores the rigid tray market and custom boxes market, examining current trends, market dynamics, technological innovations, and future prospects.

Introduction to Rigid Trays and Custom Boxes

Rigid trays are sturdy, often molded packaging containers designed to hold, display, and protect various products. They are widely used in foodservice, retail, electronics, healthcare, and other sectors where durability and presentation are paramount.

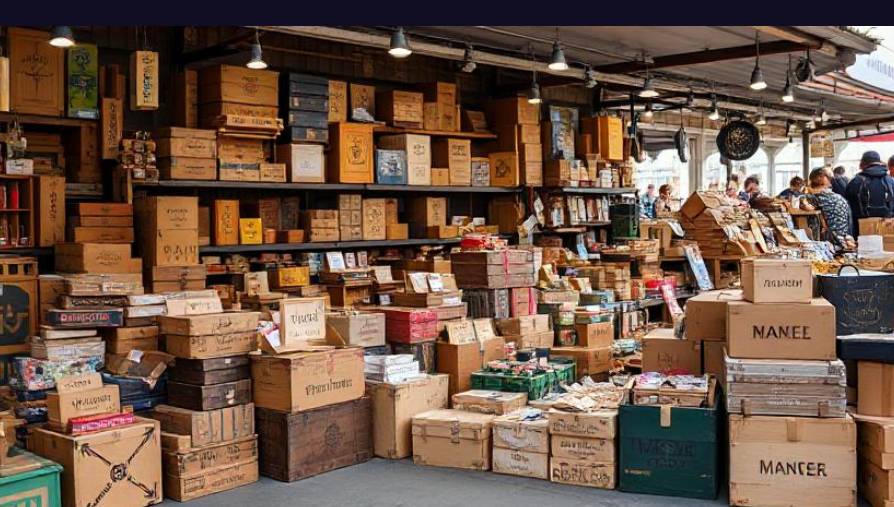

Custom boxes, on the other hand, are tailored packaging solutions crafted to meet specific branding, size, and functional requirements. They are used for everything from luxury product packaging to e-commerce shipping, offering brands a unique way to stand out in a crowded marketplace.

Both markets are experiencing significant growth, fueled by consumer preferences, technological advancements, and increasing regulatory pressures for sustainable packaging.

The Rigid Tray Market: Trends and Drivers

Growing Demand in Food and Healthcare Industries

The rigid tray market is witnessing robust growth, particularly in the food and healthcare sectors. In the food industry, rigid trays are favored for their ability to preserve freshness, prevent contamination, and enhance visual appeal. Ready-to-eat meals, deli products, and bakery items are often packaged in rigid trays for display and retail.

In healthcare, rigid trays are used for packaging sterile equipment, pharmaceuticals, and medical devices. Their durability and ability to withstand sterilization processes make them indispensable.

Sustainability and Material Innovation

Environmental concerns are transforming the rigid tray market. Companies are increasingly adopting recyclable, biodegradable, and compostable materials such as molded fiber, PET, and PP plastics. Innovations include lightweight trays that reduce material usage without compromising strength.

Technological Advancements

Automation and smart manufacturing are enhancing the efficiency of rigid tray production. Innovations such as thermoforming, injection molding, and 3D printing enable manufacturers to create complex, customized trays with high precision.

Packaging Regulations and Consumer Preferences

Stringent packaging regulations around food safety and environmental impact are pushing the market toward eco-friendly solutions. Additionally, consumers favor visually appealing, convenient, and sustainable packaging, further boosting demand.

The Custom Boxes Market: Trends and Opportunities

The Rise of E-commerce and Branding

The custom boxes market is experiencing exponential growth, driven largely by the booming e-commerce industry. Brands seek bespoke packaging that not only protects products during transit but also enhances brand recognition through unique designs.

Custom boxes allow brands to communicate their identity, values, and quality standards effectively. Features such as embossing, foil stamping, and custom printing are increasingly popular in creating memorable unboxing experiences.

Sustainability and Eco-conscious Packaging

Consumers are increasingly aware of environmental issues, prompting brands to opt for sustainable custom boxes. Recyclable corrugated fiberboard, biodegradable inks, and minimalistic designs are trending choices. Many companies are also exploring reusable packaging models to reduce waste.

Technological Innovations in Customization

Advances in digital printing, die-cutting, and automation have made custom boxes more accessible and cost-effective. Small batch runs with high customization options are now feasible, allowing brands to test different designs and marketing strategies.

Versatility Across Industries

Custom boxes are versatile and serve various industries including cosmetics, electronics, food & beverage, luxury goods, and subscription boxes. Their ability to be tailored to specific product dimensions and aesthetic preferences makes them a favorite among marketers and supply chain managers.

Market Size and Forecast

Rigid Trays Market

The rigid tray market is projected to grow at a compound annual growth rate (CAGR) of approximately 5-7% over the next five years. Factors driving this growth include increasing demand in the foodservice industry, advancements in material technology, and growing emphasis on product safety and shelf appeal.

Custom Boxes Market

The custom boxes market is expected to expand at a CAGR of around 6-8% during the same period. The surge in e-commerce, coupled with rising brand differentiation strategies, is fueling this growth. North America and Europe currently hold significant market shares, but Asia-Pacific is emerging rapidly due to expanding retail and manufacturing sectors.

Challenges and Opportunities

Challenges

- Environmental Regulations: Stricter laws require manufacturers to adopt sustainable materials, which can increase costs.

- Cost Management: Customization and advanced materials can drive up production costs, challenging profitability.

- Supply Chain Disruptions: Global supply chain issues can impact raw material availability and lead times.

Opportunities

- Innovation in Sustainable Materials: Developing cost-effective, eco-friendly materials can open new markets.

- Integration of Smart Packaging: IoT-enabled packaging for tracking, authentication, and enhanced consumer engagement.

- Expanding E-commerce Packaging Solutions: Tailored, durable, and branded packaging for online retail.

Future Outlook and Trends

The future of the rigid tray market and custom boxes market lies in sustainable innovation, technological integration, and consumer-centric design. Key trends include:

- Circular Economy Initiatives: Emphasis on recyclable and reusable packaging to reduce environmental impact.

- Personalization and Customization: Increasing demand for personalized packaging experiences.

- Smart Packaging: Incorporating sensors, QR codes, and IoT devices for enhanced functionality.

- Automation and Digital Printing: Streamlining production, reducing lead times, and enabling high-quality, short-run customizations.

Conclusion

The rigid tray market and custom boxes market are integral components of the modern packaging landscape, driven by technological innovation, consumer preferences, and regulatory pressures. As industries continue to emphasize sustainability, branding, and product protection, these markets are poised for sustained growth.

Manufacturers and brands that embrace innovation, invest in eco-friendly solutions, and leverage digital technologies will be better positioned to capitalize on emerging opportunities. Whether it’s the durability and functionality of rigid trays or the brand-enhancing capabilities of custom boxes, these packaging solutions will continue to evolve, shaping the future of product presentation and protection.

In summary, the expanding rigid tray market and custom boxes market reflect broader trends in packaging where sustainability, customization, and technological advancement are at the forefront. Companies that adapt to these trends will not only meet consumer expectations but also gain a competitive edge in an increasingly crowded marketplace

FAQs About Rigid Trays and Custom Boxes Mark

1. What are rigid trays, and what industries use them?

Rigid trays are sturdy, molded packaging containers designed to hold and display products. They are widely used in the food, healthcare, electronics, and retail industries for product protection and presentation.

2. What advantages do custom boxes offer to brands?

Custom boxes allow brands to tailor packaging to specific product dimensions and branding needs, enhancing brand recognition, improving unboxing experiences, and providing better protection during transit.

3. How is sustainability impacting the rigid tray market?

Sustainability is a key driver, with companies adopting recyclable, biodegradable, and lightweight materials to reduce environmental impact and comply with regulations.

4. What materials are commonly used for rigid trays and custom boxes?

Rigid trays often use plastics like PET, PP, or molded fiber, while custom boxes typically utilize corrugated fiberboard, paperboard, or eco-friendly alternatives.